StaClear: The First Low-Particulate Ophthalmic Syringe

TRUSTED BY RETINA SPECIALISTS

"Excellent marking and smooth action — excellent choice delivering intravitreal agents!"

– Dr. Yugen Wang, MD, Oregon Retina Center

StaClear Syringes are designed for:

Ophthalmologists

Outsourcing Facilities & Compounding Pharmacies

Ophthalmic Drug Companies

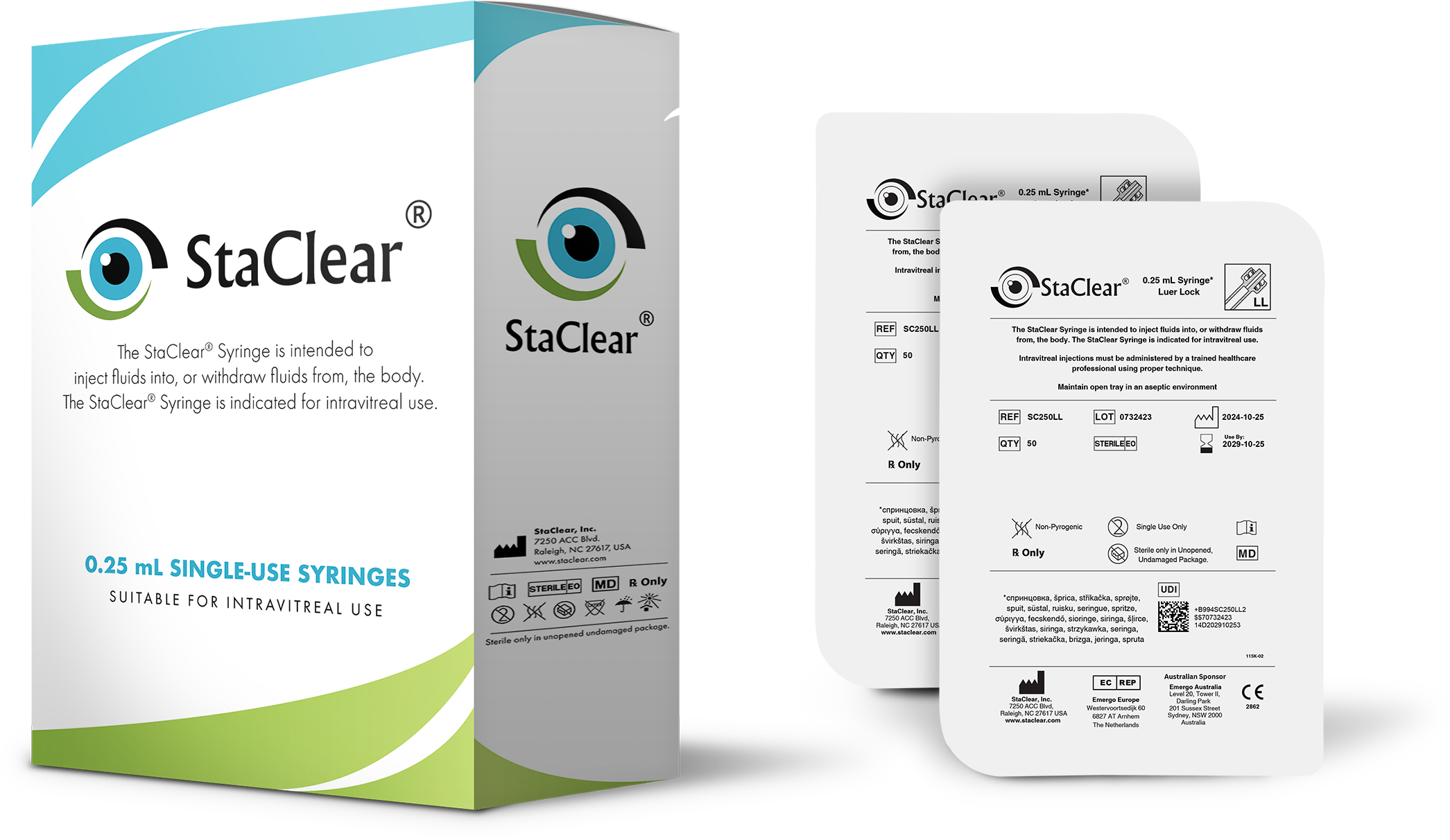

StaClear Offers 3 Types of Fillable Single-Use Intravitreal Syringes:

Attached Needle

Luer Lock

Luer Slip

WHICH STACLEAR SYRINGE IS RIGHT FOR YOU?

StaClear Attached Needle [SC250AN]

Simply uncap and use. Needle Included.

One box contains 100 syringes. 2 Trays Per Box.

StaClear Luer Slip [SC250LS]*

Slip on your favorite needle, attaches securely with low dead space.

One box contains 120 syringes. 2 Trays Per Box.

*Ophthalmic injections must use a needle indicated for ophthalmic use.

StaClear Luer Lock [SC250LL]*

Lock on your favorite needle, attaches securely with low dead space.

One box contains 100 syringes. 2 Trays Per Box.

— StaClear Luer Lock is now also available in Unit Packs —

*Ophthalmic injections must use a needle indicated for ophthalmic use.

WHY INVENT AN INTRAVITREAL SYRINGE?

The Backstory Behind the Invention of StaClear

ASRS sends alert about increased Floaters and IOP risk linked to liquid silicone oil in syringes.

Insurance companies require patients to sign waivers due to silicone oil particle risks.

FDA issues stricter guidelines for compounding intraocular injection drugs.

The industry comes to us for help. With R&D support from the National Eye Institute (National Institutes of Health) we design StaClear - the first low-particulate syringe designed with retina specialists in mind.

The StaClear Attached Needle (SC250AN) low-particulate ophthalmic syringe gets FDA 510k clearance. Its patented technology is a lubricant coating anchored to the walls of the syringe (versus liquid silicone oil in generic syringes that has been linked to adverse outcomes).

The StaClear Luer Slip (SC250LS) syringe is developed for compounding pharmacies and outsourcing facilities.

The StaClear Luer Lock (SC250LL) syringe launches in both tray and unit pack formats.

“Our syringe rejection rate went down dramatically with the StaClear syringes. This saves us money, time, and headaches from a Quality perspective. StaClear is a top-tier product.”

- Mike Basista, R.Ph., Pharm.D., BCSCP, Supervising Pharmacist, RC Outsourcing

If you’re supplying to retina specialists, you’ll enjoy Mike’s perspective on the technical reasons he selected StaClear and the feedback he’s received from his doctor clients.

6 REASONS WHY RETINA SURGEONS CHOOSE STACLEAR FOR DRUG DELIVERY

REASON #1: IMMOBILIZED SILICONE COATING

StaClear syringes meet USP <789> for low particles. Engineered to minimize silicone oil in the drug product.

REASON #2: PRECISION DOSING

Retina specialists inject very small amounts of drug in the eye. We designed our syringes to suit their precise dosing needs. We even added a custom graduation mark on our Luer Lock syringes at the request of our pharmaceutical clients.

REASON #3: OPTIMIZED DESIGN

All 3 StaClear Syringes (Attached Needle, Luer Lock & Luer Slip) are designed to reduce dead space, saving up to $10-15 of drug wastage.

REASON #4: CONTROLLED INJECTION EXPERIENCE

Elastomer piston ensures sealing integrity, mitigating a known risk in silicone-free syringes.

REASON #5: IMPROVED ACCURACY

StaClear Syringes offer better dosing accuracy than 1mL syringe types.

REASON 6: OPHTHALMIC-SAFE MATERIALS

Meets chemical and biocompatibility standards for ophthalmic use.

"The StaClear syringe provides consistent dosage and a smooth injection experience. Very easy to use and work with!"

– Dr. Alan Sheyman, MD, New York Eye and Retina

All 3 StaClear Syringe Types (Attached Needle, Luer Slip, and Luer Lock) are Available in Easy-to-Use Tray Packs.

There are 2 Trays Per Box.

| Product | Model | Box |

|---|---|---|

| Attached Needle Syringe | SC250AN | 100 Syringes [2x50 Tray Pack] |

| Luer Slip Syringe | SC250LS | 120 Syringes [2x60 Tray Pack] |

| Luer Lock Syringe | SC250LL | 100 Syringes [2x50 Tray Pack] |

| 25 Syringes [1x25 Unit Packs] |

StaClear Luer Lock Syringes are also available in Unit Packs.

Research Funded by National Institutes of Health (NIH)

The National Eye Institute (through its SBIR grant program) at the NIH championed this important research. Thanks to its support, StaClear is the first low-particulate intravitreal syringe designed, developed, and commercialized via the SBIR program to serve the needs of the ophthalmic industry.

NEW TO STACLEAR? READ THE FREQUENTLY ASKED QUESTIONS CLIENTS TYPICALLY ASK.

“After years of R&D in close collaboration with retina specialists, compounding pharmacies, and pharma companies, it is gratifying to see a groundswell of demand for StaClear, and receive so much support from the entire industry.

Get in touch via the form below to start the conversation. We typically respond within 24-48 hours.”

- Vinay Sakhrani, Founder & CEO, StaClear